|

|

The Wandering Wind Tunnel

Abstract:

The Wandering

Wind Tunnel is a complete stand alone, sub scale wind tunnel that is small

enough to be transported on the back of a pick-up truck and large enough

for meaningful data. Six students from Barberton High School were selected

to work at NASA Lewis Research Center in Cleveland, Ohio for five weeks

during the summer of 1994 to begin a research project that would lead

them to both a practical and accurate design. They were then to build

the small portable wind tunnel when returning to Barberton High School.

The wind tunnel, when complete, will eventually travel around to area

high schools for aerospace testing. It is hoped that it will be a catalyst

for the application of computational fluid dynamics in the high schools

and also provide valid data that can be electronically transferred while

networking to other remote science classrooms. Educational Paper for Supercomputing

1995 The Wandering Wind Tunnel Project A project for the design and construction

of a subsonic, small-scaled wind tunnel to be used to explain aerospace

engineering fundamentals to pre-college students; the completed wind tunnel

will be portable and will travel to Northern Ohio high school sites for

data acquisition throughout the school year.

Student

Authors:

Todd Buxton

Todd Fleet

Davelene Israel

Jeffrey Heilman

Joshua Humphrey

James Mongiardo

Barberton

High School 489 Hopocan Avenue Barberton, OH 44203 216-753-1084 fax 216-848-5517

January

30, 1995 Presenting Author: Carol Hodanbosi Physics Instructor Barberton

High School 489 Hopocan Avenue Barberton, OH 44203 216-753-1084 fax 216-848-5517

1.0

Introduction

2.0 Design Team

3.0 Wind Sections

3.1 Test Section

3.2 Contraction Cone

3.3 Settling Chamber

3.4 Diffuser and Fan Housing

4.0 Data Acquistion

5.0 Safety Features

6.0 Cost

7.0 Conclusion

1.0

Introduction

The Wandering Wind Tunnel Project was initiated to provide a way for high

school students to learn about aerodynamics and computational fluid dynamics

through experimentation on a portable wind tunnel. The wind tunnel itself

was designed to be a complete, stand-alone, sub-scale subsonic project;

small enough to be transported on the back of a pick-up truck, but large

enough for the production of meaningful data. The wind tunnel will provide

data to the various Ohio high schools involved in the HPCC (High Performance

Computing and Communications) K-12 pilot project, a program designed to

bring technology into the science and mathematics classroom environment.

The data collected will be analyzed on high performance computers funded

by HPCC, and will provide an opportunity for data transfer among the schools

through an electronic network.

2.0

The Design Team

The design team, which planned and constructed the wind tunnel, consisted

of six students from Barberton High School. The students initially involved

in the project were: Todd Buxton, senior; Todd Fleet, sophomore; Nicholas

Grinder, sophomore; Jeff Heilman, junior; Josh Humphrey, junior; and Davelene

Israel, junior. James Mongiardo, a junior, also became involved with the

project at a later date, when Nicholas Grinder moved to another school.

These students were previously involved in a Supercomputing Program with

Carol Hodanbosi, physics teacher at Barberton High School. The Supercomputing

Program was also funded by HPCC and NASA Lewis Research Center as part

of a K-12 pilot program. The project mentor was Dr. Colin Drummond, an

aerospace research engineer at NASA Lewis Research Center, in Cleveland,

Ohio. Funding for the project came from AIAA, (American Institute of Aeronautics

and Astronautics), the northeastern Ohio branch, the NASA Lewis Research

Center in Cleveland, Ohio, in conjunction with the HPCC K-12 pilot program,

and OAI (Ohio Aerospace Institute).

3.0

The Wind Tunnel Components

The wind tunnel is comprised of five main parts, listed in order from

front to back: the settling chamber, the contraction cone, the test bed,

the diffuser, and the fan housing with a variable speed motor. Also included

will be an IBM 486SX computer, suitable software for air flow analysis,

an A/D converter, a multiplexer, thermocouples, temperature and pressure

probes, and a force balance model mount.

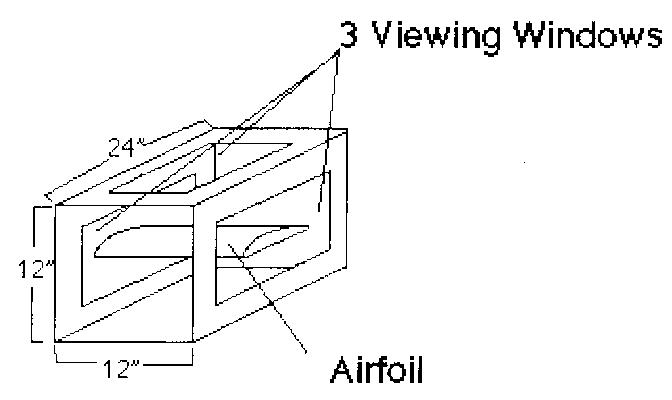

3.1

Test Section

The deciding factor for almost every component of the wind tunnel was

the size of the test bed, which, in turn, is determined by the size of

the object to be tested. The test bed is shown in figure 1.

The entire

wind tunnel had to be small enough to fit inside the bed of a pick-up

truck while being transported. Based on this restriction, the test section

was designed as 1' x 1' x 2'. The test section was made of 1 1/2" angle

irons, and has three acrylic viewing windows. Each end of the test bed

has 1 1/2" metal angle flanges to bolt to the other sections. The flanges

allows for easy disassembly, another requirement for the portability of

the wind tunnel.

The entire

wind tunnel had to be small enough to fit inside the bed of a pick-up

truck while being transported. Based on this restriction, the test section

was designed as 1' x 1' x 2'. The test section was made of 1 1/2" angle

irons, and has three acrylic viewing windows. Each end of the test bed

has 1 1/2" metal angle flanges to bolt to the other sections. The flanges

allows for easy disassembly, another requirement for the portability of

the wind tunnel.

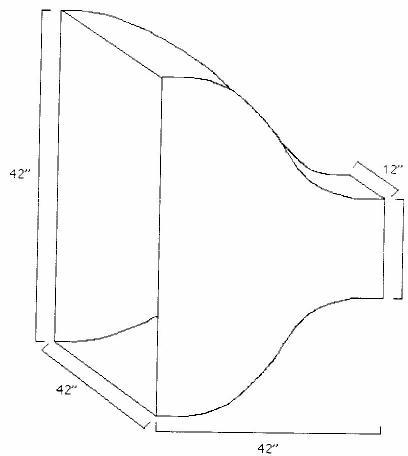

3.2

The Contraction Cone

The second section of the wind tunnel designed was the contraction cone

(figure 2), which proved to be the most difficult section as far as design

and materials.

The contraction cone's purpose is to take a large volume

of low velocity air and reduce it to a small volume of high velocity air

without creating turbulence. The size of the large end, nearest the settling

chamber was set at 3.5' x 3.5'. Many of the ratios the design team used

were selected with the guidance of the book "Low-Speed Wind Tunnel Testing"

by William Rae, Jr and Alan Pope. The small end of the contraction cone

was set at 1' x 1' to fit directly onto the test section. The shape of

the contraction cone was a cubic curve, modeled after larger wind tunnels.

The contraction cone originally was designed to be made out of fiberglass,

but due to difficulties involved with heating and molding it, it was decided

by the group to be made out of 14 gauge sheet metal instead. The sheet

metal also has metal flanges on each side to bolt together with the other

sections.

The contraction cone's purpose is to take a large volume

of low velocity air and reduce it to a small volume of high velocity air

without creating turbulence. The size of the large end, nearest the settling

chamber was set at 3.5' x 3.5'. Many of the ratios the design team used

were selected with the guidance of the book "Low-Speed Wind Tunnel Testing"

by William Rae, Jr and Alan Pope. The small end of the contraction cone

was set at 1' x 1' to fit directly onto the test section. The shape of

the contraction cone was a cubic curve, modeled after larger wind tunnels.

The contraction cone originally was designed to be made out of fiberglass,

but due to difficulties involved with heating and molding it, it was decided

by the group to be made out of 14 gauge sheet metal instead. The sheet

metal also has metal flanges on each side to bolt together with the other

sections.

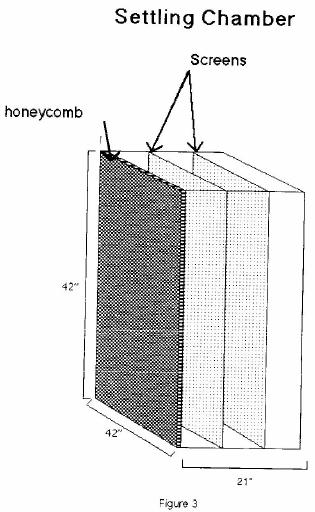

3.3

The Settling Chamber

The settling chamber was designed after the contraction cone. This section

is the front section of the wind tunnel and is placed onto the contraction

cone (figure 3).

The purpose of the settling chamber is to `straighten'

the air flow as the wind tunnel draws air in from the surrounding air,

channeling the ambient air. The settling chamber's cross section dimensions

are 3.5' x 3.5', and match up with the dimensions of the contraction cone.

It will be made out of 1/2" plywood and will have 1 1/2" angle irons as

a flange to bolt it to the contraction cone. Its length is 21" to accommodate

three different flow straightening devices. The first of the flow straightening

devices is the honeycomb (figure 3). The honeycomb is a series of tubes

laid lengthwise in the air stream. Its purpose is to allow the air to

only enter in one direction, parallel to the airflow of the tunnel so

that cross-flow velocities will not cause swirling winds in the tunnel.

The design team decided upon 1/8" diameter straws cut into 1" pieces for

their honeycomb. The straws will be placed at the very front of the settling

chamber, aligned parallel to the air flow and held in place by double-sided

masking tape. The second and third flow-straightening devices are screens

(figure 3). Their purpose is to make the velocities of the wind in the

wind tunnel equal by eliminating fast and slow air velocities. As the

air passes through the screens, the resulting drop in pressure across

the screen creates constant air speed in the tunnel. The two screens will

be approximately 6" apart from each other and will be placed 6" behind

the honeycomb. All three of the flow straighteners will be removable for

easy cleaning and maintenance.

The purpose of the settling chamber is to `straighten'

the air flow as the wind tunnel draws air in from the surrounding air,

channeling the ambient air. The settling chamber's cross section dimensions

are 3.5' x 3.5', and match up with the dimensions of the contraction cone.

It will be made out of 1/2" plywood and will have 1 1/2" angle irons as

a flange to bolt it to the contraction cone. Its length is 21" to accommodate

three different flow straightening devices. The first of the flow straightening

devices is the honeycomb (figure 3). The honeycomb is a series of tubes

laid lengthwise in the air stream. Its purpose is to allow the air to

only enter in one direction, parallel to the airflow of the tunnel so

that cross-flow velocities will not cause swirling winds in the tunnel.

The design team decided upon 1/8" diameter straws cut into 1" pieces for

their honeycomb. The straws will be placed at the very front of the settling

chamber, aligned parallel to the air flow and held in place by double-sided

masking tape. The second and third flow-straightening devices are screens

(figure 3). Their purpose is to make the velocities of the wind in the

wind tunnel equal by eliminating fast and slow air velocities. As the

air passes through the screens, the resulting drop in pressure across

the screen creates constant air speed in the tunnel. The two screens will

be approximately 6" apart from each other and will be placed 6" behind

the honeycomb. All three of the flow straighteners will be removable for

easy cleaning and maintenance.

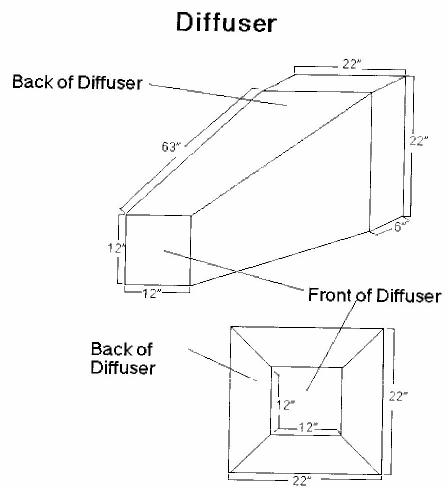

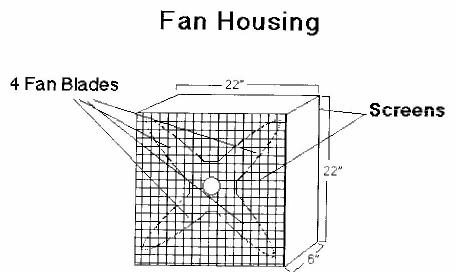

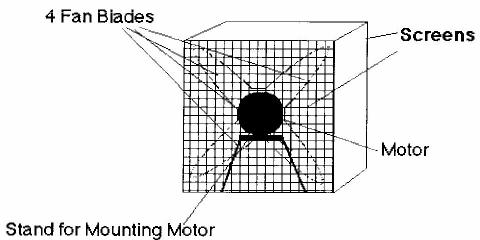

3.4

The Diffuser and Fan Housing

The diffuser section (figure 4) of the wind tunnel is necessary to reduce

any air turbulence that could lead back into the test section.

The angle

of the diffuser is based on a ratio of surface area of the end of the

diffuser to the surface area of the front of the diffuser. The dimensions

of the front opening are 12" x 12" and the dimensions of the end opening

are 22" x 22". This gives a ratio of 3.36 to 1. Using this ratio, the

angle of the diffuser was set at 4.8 degrees. The diffuser is 63" long

and will connect to the test section with flanges similar to the ones

used to join the test section and the contraction cone. Following the

diffuser is a fan housing (figure 5) to hold a four blade fan controlled

by a variable speed motor.

The angle

of the diffuser is based on a ratio of surface area of the end of the

diffuser to the surface area of the front of the diffuser. The dimensions

of the front opening are 12" x 12" and the dimensions of the end opening

are 22" x 22". This gives a ratio of 3.36 to 1. Using this ratio, the

angle of the diffuser was set at 4.8 degrees. The diffuser is 63" long

and will connect to the test section with flanges similar to the ones

used to join the test section and the contraction cone. Following the

diffuser is a fan housing (figure 5) to hold a four blade fan controlled

by a variable speed motor.

The fan housing will be 25" x 25" wide and

6" in length. The fan will have two screens, one in front and one in back,

for safety purposes. The motor will be mounted on a stand with rubber

pads (figure 6) to reduce the amount of vibration on the wind tunnel.

The fan housing will be 25" x 25" wide and

6" in length. The fan will have two screens, one in front and one in back,

for safety purposes. The motor will be mounted on a stand with rubber

pads (figure 6) to reduce the amount of vibration on the wind tunnel.

4.0

The Data Acquisition System

The main types of test data in any wind tunnel are lift and drag. The

design team used a sting and thrust balance system to measure the effects

of lift and drag on their models. Lift and drag are measured by using

a series of springs, a pivot, and a strain gauge, which are all part of

the thrust balance system. When the air passes over the model, the pivots

and springs create a tighter or looser strain on the gauge. Strain gauge

sensors electrically respond to the change and to its intensities, and

send an voltage change to the A/D board. The A/D board converts the electric

signal into a digital computer language. The computer collecting the data

will be an IBM 486SX, with sixteen input channels. Total and static pressure

readings will be another important source of data. This data provides

a way to find the true air velocity in the tunnel. The wind tunnel will

have four pitot tubes, which will be able to measure static pressure and

total pressure. By substituting in appropriate pressure-velocity equations,

one can determine the velocity from the two pressures. true air speed

= square root of ((2 x dynamic pressure) / air density) dynamic pressure

is measured in pounds / square foot air density is measured in slugs /

cubic foot Flow patterns are the most easily viewed test. The design team

plan on using smoke, tufts, and paint to visualize flow patterns in the

wind tunnel. Smoke will be used to show turbulence around the model. Paint

and tufts will be the least expensive and most effective way to illustrate

flow on the surface. Air foils of various designs will be used in the

wind tunnel. Student projects in science and physics classes could design

airfoils from various airplanes. Additional experiments such as dimpled

versus non-dimpled golf balls and small models of automobiles and downhill

skiers have been considered. The sting, which is the support for the models,

will be adaptable to almost any model. Proper placement of the sting and

model in the test bed will be essential to quality data collection. In

addition to the sting placement, there are also proper component placements.

The pressure rakes, pitot tubes, thermocouples, and thermometer probes

must be placed in way to avoid disturbing the air flow. An analog to digital

(A/D) sixteen channel, 100 kHz converter board, a terminal connector,

and a multiplexer are necessary in the data collection process. Appropriate

flow analysis software will be selected that is simple to operate, has

a large range of functions, and that also has graphic display capabilities.

The five important measurements that need to be found in the low speed

wind tunnel are dynamic pressure, static pressure, total pressure, temperature

and turbulence. Thermocouples, temperature probes, pressure rakes, pitot

tubes and a force balance on the mounting sting are required for the wind

tunnel to generate accurate data.

5.0

Safety Features

Since this machinery will involve the active participation of high school

students, safety is an important factor. To ensure the safety of the individuals

operating the wind tunnel there will be screens located in front of and

behind the fan. This feature will not only protect the operator, but will

also keep the test model from being destroyed by the fan if it slides

from its mounting and out of the test section. Protective caps will be

placed on the front of the settling chamber and the back of the motor

during transportation and periods of low use will lower the amount of

dust build up. A keyed switch will be on the wind tunnel motor so that

it cannot be operated without supervision. Another very important feature

of the wind tunnel is the emergency stop wire. This wire will run along

the outsides of the tunnel and in cases of emergency it can be pulled.

The stop wire will be attached to a shut off switch to automatically stop

the fan.

6.0

Cost

The cost restrictions imposed on the design team involved only the actual

wind tunnel materials, along with the motor and fan. The cost of the computer,

software, A/D board and probes were itemized separately. The design team

initially had a budget of $500.00. They found that with a single speed,

A.C., 1 horsepower motor they would remain inside the budgetary guidelines,

but their experiments would be limited to a single setting. Although the

cost of a variable speed motor, D.C. motor was considerably more, as shown

below, it would provide more flexibility in their experimental data: Variable

Speed Non-variable Speed motor $320 motor $220 controller $370 ______

_____ total $690 $220 The design team decided that the variable speed

motor was well worth the extra expense. The following list shows the cost

of the rest of the materials that were needed for the structure of the

wind tunnel. The contraction cone was contracted out to a local machinist,

so the price listed includes both labor and materials. The straws used

in the settling chamber were donated by a straw manufacturer. Each plastic

straw was 7 3/4 inches in length and one-eighth inch diameter. They were

cut into one inch lengths, using a machine that one of the students made

with the assistance of his father. The design team estimated that they

needed more than 16,000 straws for the settling chamber. The wiring was

required for both the key and selector switch to the motor. The students

completed this wiring by themselves. fan $ 60 wood $180 acrylic glass

$ 30 contraction cone $180 angle irons $ 30 wiring $300 tape $ 20 straws

$ 90 ____________________ total $890 + motor+ controller = $1580

7.0

Conclusion

The wind tunnel project was and will continue to be a learning experience

for all the participants. During this project, the design team learned

that responsibility and teamwork was important for the wind tunnel to

be properly designed and built. At first, it was difficult for the six

high school students to learn to compromise. Each had their own ideas

and had to learn to listen to other opinions that had equal merit. Eventually,

however, they learned to value each member's contribution and worked together

well. Another important aspect of this project was the contribution of

expertise of several of the students' parents. The summer internship gave

each of the students invaluable real world experiences that included;

economics, time constraints, size and weight restrictions on the design

itself, cooperative interaction,interrogation of researchers for important

information, and finally, after all the research was done, critical decision-making.

At this time, the wind tunnel is nearly complete. The design team has

finished most of the important sections, with only one section remaining.

The metal shop class has recently made the motor stand and mount from

the team's specifications. The A/D apparatus, pressure and temperature

probes have been installed and work correctly.The team has to find a way

to reverse the direction of the fan blades (it was designed to exhale

not inhale) and still attach to the motor. A new metal sleeve must be

made for the attachment of the blades to the motor. Plans for the 1995-96

year will include the following projects: Physical science and physics

classes, along with two fourth grade classes will work cooperatively to

develop experiments for the wind tunnel. Together they will test existing

objects that they may choose, such as golf balls and model cars and planes.

They will also design shapes from modeling clay to be placed in the test

bed. Sensors located in the test section are connected to a computer,

whose software is designed to analyze various air flow patterns. The students

will use the data derived from these experiments to predict how other

objects will behave in the wind tunnel. They will research how air temperature,

air density, humidity, air speed, and the geometry of the objects affect

the air flow. Based on the results of the experiments, they will make

generalizations about good aerodynamic design. The data that they derive

from this activity can be sent via the internet to other schools interested

in acquiring flow data. After Barberton High School has completed its

tests, the wind tunnel will 'wander' to other sites for further experimentation.

The wind tunnel hopefully will become a catalyst for creativity, with

each school creating their own models and experiments for data acquistion.

Bibliography

Rae Jr., William H. and Pope, Alan. Low-Speed Wind Tunnel Testing. New

York,Wiley & Sons, 1984, pages 37-119,126-141,153-183.

Navigation ..

- Beginner's Guide Home Page

|