|

|

+ Text Only Site

+ Non-Flash Version

+ Contact Glenn

|

|

|

|

|

Beginner's

Guide to Propulsion

Turbine

Engine Identification

Answers

Answers

will vary. Suggested answers are shown below:

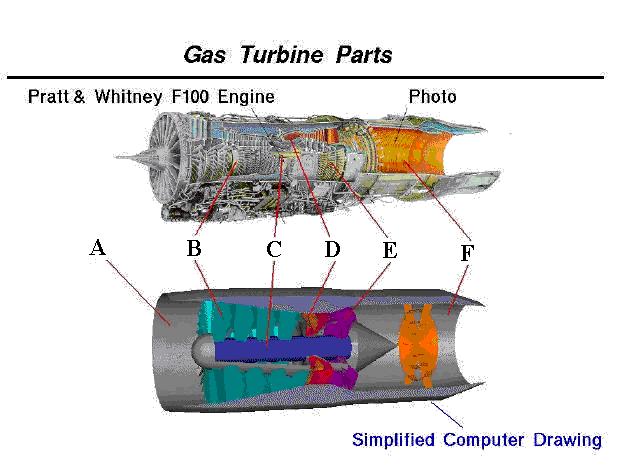

- Use

the Gas Turbine Parts section located in the Propulsion

Index of the Beginner's Guide

to Propulsion to match the correct letter from above with the

listed part. Write the corresponding letter for each part in the space

to the right of the word.

|

Nozzle

|

F

|

|

Turbine

|

E

|

|

Compressor

|

B

|

|

Shaft

|

C

|

|

Burner

|

D

|

|

Inlet

|

A

|

- Answer the following

questions about Turbine Engine Parts and Engine Component

Analysis using the Beginner's

Guide to Propulsion.

- Why is the inlet

lip of a supersonic airplane's engine sharper than the inlet lip of

a subsonic airplane?

The inlet lip is sharpened to minimize

the performance losses from shock waves that occur

during supersonic flight.

- What is the purpose

of the central cone in the "Axisymetric Supersonic" engine?

Some supersonic inlets, like the one at

the upper right,

use a central cone to shock the flow down to subsonic speeds.

- What is the purpose

of the stators in the compressor? Other

rows, called stators, are fixed and do not rotate. The job of the

stators is to both

increase pressure and to keep the flow from spiraling around the axis

by bringing the flow back parallel to the axis.

- What is the advantage

of having a rectangular nozzle on a jet engine?

This allows the exhaust flow to be easily

deflected. Changing the direction of the thrust with the nozzle makes

the aircraft much more maneuverable.

- What is "spillage

drag?" Spillage drag, as the name implies,

occurs when an inlet "spills" air around the outside instead of conducting

the air to the compressor face. The amount of air that goes through

the inlet is set by the engine and can change with altitude and throttle

setting. The inlet is usually sized to pass the maximum airflow that

the engine can ever demand and, for all other conditions, the inlet

will spill the difference between the actual engine airflow and the

maximum air demanded. As the air is spilled over the external cowl

lip, the air is accelerated and the pressure decreases. This produces

a lip suction effect, which partially cancels out the drag due to

spilling.

- What is meant

by "distortion" in reference to inlet performance? As

the air is brought from free stream to the compressor face, the flow

may be distorted by the inlet. At the exit of the inlet (the compressor

face), one portion of the flow may have a higher velocity, or higher

pressure, than another portion. The flow may be swirling or some section

of the boundary layer may be thicker than another section because

of the inlet shape. The rotor blades of the compressor move in circles

around the central shaft. As the blades encounter distorted inlet

flow, the flow conditions around the blade change very quickly. The

changing flow conditions can cause flow separation in the compressor

(a compressor stall) and can cause structural problems for the compressor

blades.

- What

is the difference between an axial compressor and a centrifugal compressor?

The

flow through the axial compressor travels parallel to the axis of

rotation. The flow through the centrifugal compressor is turned perpendicular

to the axis of rotation.

- Why

did designers change from centrifugal compressors to axial compressors?

An

average, single-stage centrifugal compressor can increase the pressure

by a factor of 4. A similar, single-stage axial compressor increases

the pressure by only a factor of 1.2. But it is relatively easy to

link together several stages and produce a multistage axial compressor.

In the multistage compressor, the pressure is multiplied from row

to row (8 stages at 1.2 per stage gives a factor of 4.3). It is much

more difficult to produce an efficient multistage centrifugal compressor

because the flow has to be ducted back to the axis at each stage.

Because the flow is turned perpendicular to the axis, an engine with

a centrifugal compressor tends to be wider (greater cross-sectional

area) than a corresponding axial. This creates additional undesirable

aircraft drag. Centrifugal compressors are also less efficient than

axial compressors.

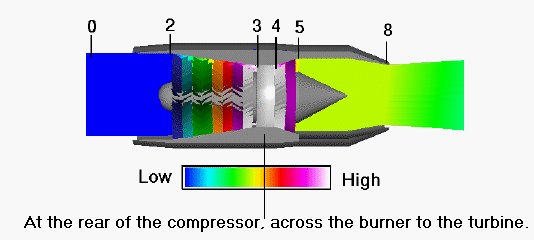

- At

what point in the turbojet engine is the pressure the highest?

-

How

does the nozzle produce thrust? The

nozzle converts the high pressure and temperature into high velocity.

Because the exit velocity is greater than the free stream velocity,

thrust is created.

|

Related Pages:

Standards

Worksheet

Activity

Propulsion Activity Index

Propulsion Index

|

|

|

|